Linkage Bearing Rebuild Kits for Older GasGas Motorcycles | LRK-G-006

Restore smooth rear suspension performance with a premium GasGas linkage bearing rebuild kit from Factory Links.

This linkage bearing rebuild kit is engineered specifically for older GasGas enduro and off-road models, delivering OEM-quality fit, durability, and performance. Each kit includes heavy-duty full-complement needle bearings, precision-machined collars, hardened pins, and NBR dust seals—manufactured to strict OEM material, dimensional tolerance, hardness, and surface finish standards.

Designed for aggressive off-road and racing conditions, our GasGas linkage bearing kit provides optimal load distribution under high shock loads and oscillating rear suspension movement. The result is smoother articulation, reduced play in the linkage system, and extended service life in mud, water, and extreme terrain.

Every kit includes all components required for a complete rear suspension linkage rebuild. In addition, this kit includes the lower shock absorber service kit components, providing a comprehensive solution for servicing both the linkage assembly and lower shock mounting point in one package.

Every kit includes all components required for a complete rear suspension linkage rebuild. In addition, this kit includes the lower shock absorber service kit components, providing a comprehensive solution for servicing both the linkage assembly and lower shock mounting point in one package.

Factory-level fit. Race-ready durability. A complete rear suspension bearing solution for GasGas off-road motorcycles.

Information

Factory Links premium linkage bearing rebuild kits are engineered from the ground up to deliver OEM-quality performance—without the high cost of purchasing individual components from a dealership.

Each kit contains all required needle bearings, collars, pins, and dust seals needed for a complete suspension linkage overhaul. Manufactured to meet strict OEM standards for material quality, dimensional tolerances, hardness, and surface finish, our components ensure proper load distribution, smooth suspension movement, and long service life in off-road conditions.

By consolidating all critical linkage components into one comprehensive kit, Factory Links provides a cost-effective and efficient alternative to dealer replacement parts—while maintaining the fit, durability, and reliability riders expect from OEM-level service.

Technical Details

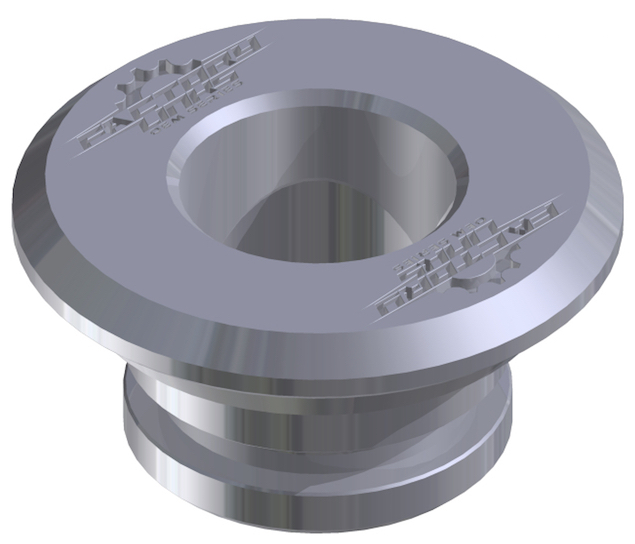

PINS

Precision-machined and induction-hardened linkage pins manufactured from SAE52100 high-grade bearing steel. Hardened above HRC60 and precision ground to meet OEM dimensional tolerances—ensuring smooth pivot operation and long service life.

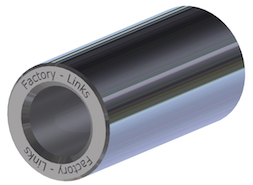

COLLARS

Precision-machined linkage collars are manufactured from automotive-grade SPCC steel, hardened to HRC48, polished, and zinc-plated for enhanced corrosion resistance. Designed to maintain proper bearing alignment and load distribution within the suspension linkage system, these collars ensure smooth pivot movement and long-term durability in demanding off-road conditions.

Precision-machined linkage collars are manufactured from automotive-grade SPCC steel, hardened to HRC48, polished, and zinc-plated for enhanced corrosion resistance. Designed to maintain proper bearing alignment and load distribution within the suspension linkage system, these collars ensure smooth pivot movement and long-term durability in demanding off-road conditions.

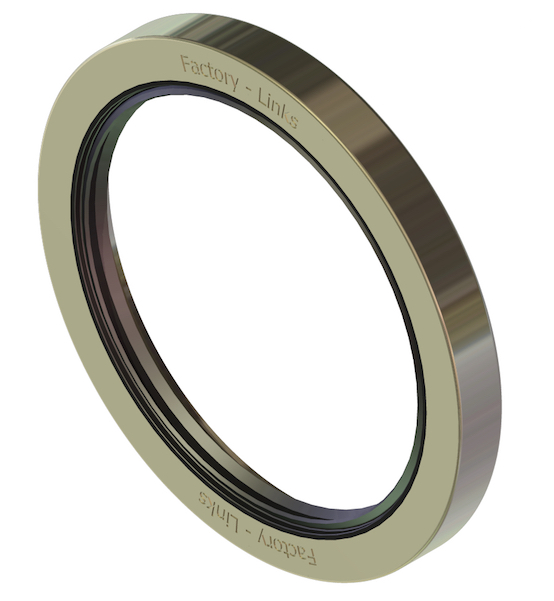

DUST SEALS

NBR (Nitrile Butadiene Rubber) dust seals molded to exact OEM specifications. Designed to block mud, water, and abrasive contamination from entering the linkage bearing system.

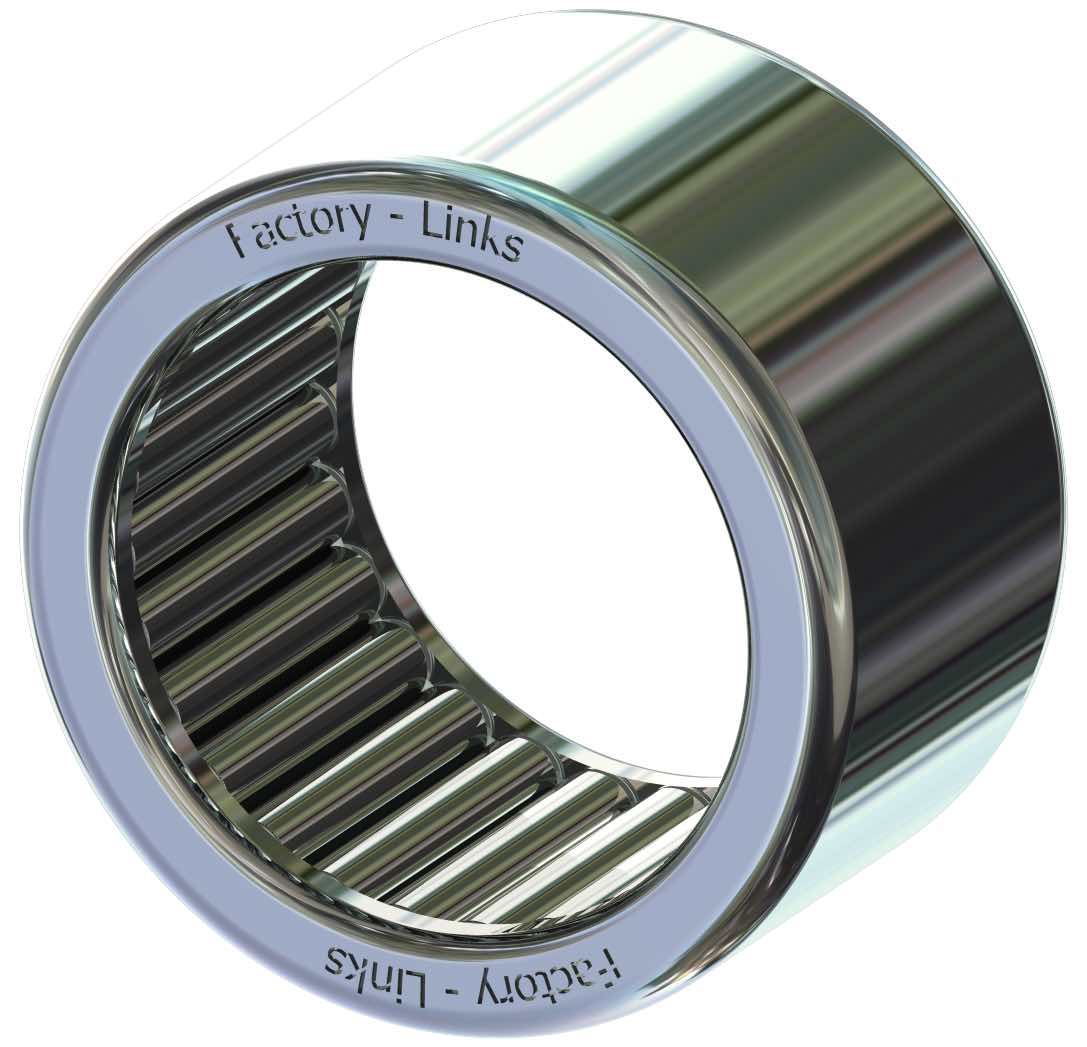

HEAVY DUTY NEEDLE BEARINGS

Full-complement drawn cup needle bearings manufactured from hardened SPCC steel. Internal clearances are specified for high shock loads and oscillating movement typical of off-road motorcycle linkage systems.

Fitment

| Kit / Fitment |

Linkage Bearing kit |

|---|---|

| Manufacturer |

GAS GAS |

| Model | HALLEY 2T 125 EH (2009-2009) HALLEY 2T 125 SM (2009-2009) |

| Manufacturer |

GAS GAS (OLD) |

| Model | EC 125 (2001-2011) EC 200 (1999-2011) EC 250 (1996-2011) EC 250 F 4T (2010-2012) EC 250 F 4T (2010-2012) EC 300 (1999-2011) MC 125 (2001-2009) MC 250 (1999-2009) MX 125 (2002-2007) MX 250 (2002-2007) SM 125 (2002-2008) SM 250 (2002-2008) |